If you equip commercial vehicles with aluminum rims, two scenarios can arise:

a) The vehicle's wheel studs are long enough for aluminum rims

How can you check that?

Measure the length of the wheel studs from the surface of the hub that contacts the wheel to the outer end of the stud. The minimum length of the bolt is for

- metric threads M18, M20 or M22:

2x the thickness of the Alcoa® Wheels rim

+ Height of the standard nut

+ 3mm - inch thread (Scania all models or Volvo before 2005):

2x the thickness of the Alcoa® Wheels rim

+ Height of the standard nut

+ 2 full threads

If the thread is long enough, you can use the standard nuts. For optical reasons, we recommend using stainless steel caps oder chrome-plated plastic caps or to cover the nuts. Chromed plastic caps have the advantage that they do not cause any chafing on the contact surface with the rim.

b) The wheel bolts of the vehicle are too short for aluminum rims

In this case, please select the rim so that you can use sleeve nuts. The sleeve nuts have additional threads in the sleeve, which are screwed through the bolt hole of the rim and thus ensure the required screw-in depth. Vehicles with

- M18 bolts require rims with a 26 mm bolt hole diameter

- M20 bolts require rims with a 30 mm bolt hole diameter

- M22 bolts require rims with a 32 mm bolt hole diameter.

Make sure you order the right wheels.

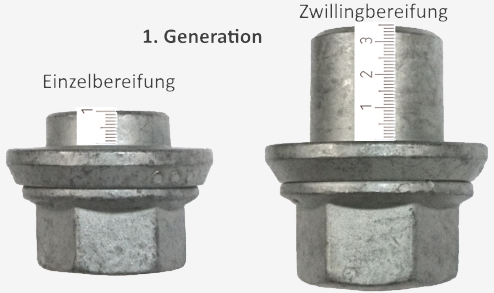

Old and new sleeve nuts

Compared to the current generation, the first generation of sleeve nuts had very long threaded sleeves for attaching twin wheels.

1st generation sleeve nuts:

- for single tires the sleeve had a length of approx. 10mm,

- for twin tires of approx. 35 mm

2nd generation sleeve nuts:

- for single tires the length of the sleeve is approx. 9mm,

- for twin tires, however, only approx. 17mm

Please note that when fastening with sleeve nuts you cannot screw steel and aluminum wheels combined on one axle position, as the sleeve of the nut extends through the outer rim and would touch the steel rim, causing pressure damage there. Apart from that, the combined use of steel and aluminum rims is not recommended due to the resulting contact corrosion.

English (United Kingdom)

English (United Kingdom)  Deutsch (Deutschland)

Deutsch (Deutschland)